SpeedSF Blog

Every Build Has a Story – Meet the Cars of SpeedSF

Markus’ EP3 Civic: Rapid Ascent

Sim racing laid the foundation, and then a milder EP3 before this one. When a track acquaintance put this K20A-swapped Civic up for sale, Markus didn’t hesitate to buy. With only 200 horsepower, it can lap Laguna in 1:40.

Justin’s Trans Am: Party Animal

With a hope for a powerful head-turner with classic styling, Justin Hertel picked up this 1988 Trans Am and swapped an LSA motor into it. As he learned, big power comes with its setbacks.

Spencer’s GT3: Scoping New Territory

Eager to track a Porsche but worried about the expense, Spencer Kimball had to consider if it was worth leaving his E92 M3 behind for a lightly used 991.1 GT3. As he learned, the process wasn’t nearly as painful as he worried it’d be.

Rafael’s FD3S RX-7: Pipe Dream

After dreaming about one of his Gran Turismo hero cars for many years, Rafael Guerrero was able to trade up through over a dozen RX-7s and eventually snag this gorgeous 1992 RX-7 Type R.

Chris’ DCT-Swapped Miata: Grasping the Big Picture

By sourcing the right parts from retired race cars, using all his industry know-how, and taking the leap to install a BMW DCT in his NB, Chris Watson’s found an inspiring recipe for a reliable track-tuned Miata that can lap Laguna in 1:33.

Piers’ 240Z: From First Principles

After rebuilding a carbureted bike in his apartment’s underground parking lot, Piers bought a pretty 240Z and began learning how to make an old Datsun work on track.

Fan’s NC Miata: Truncating Ten Years

Proper planning and dedication to simulator racing helped Fan learn the skills needed to run fast laps in roughly a third of the time it takes people without a well-researched plan. Now, he laps Laguna Seca in this mildly modified MX-5 in the 1:45-range.

Abdul’s E46 M3: Checking All Boxes

It didn’t take Abdul long to realize that seat time was all-important, so he made a point to avoid the typical impediments to his progress. Then he bought a versatile M3, had the right guys set it up, and put in his time learning his craft.

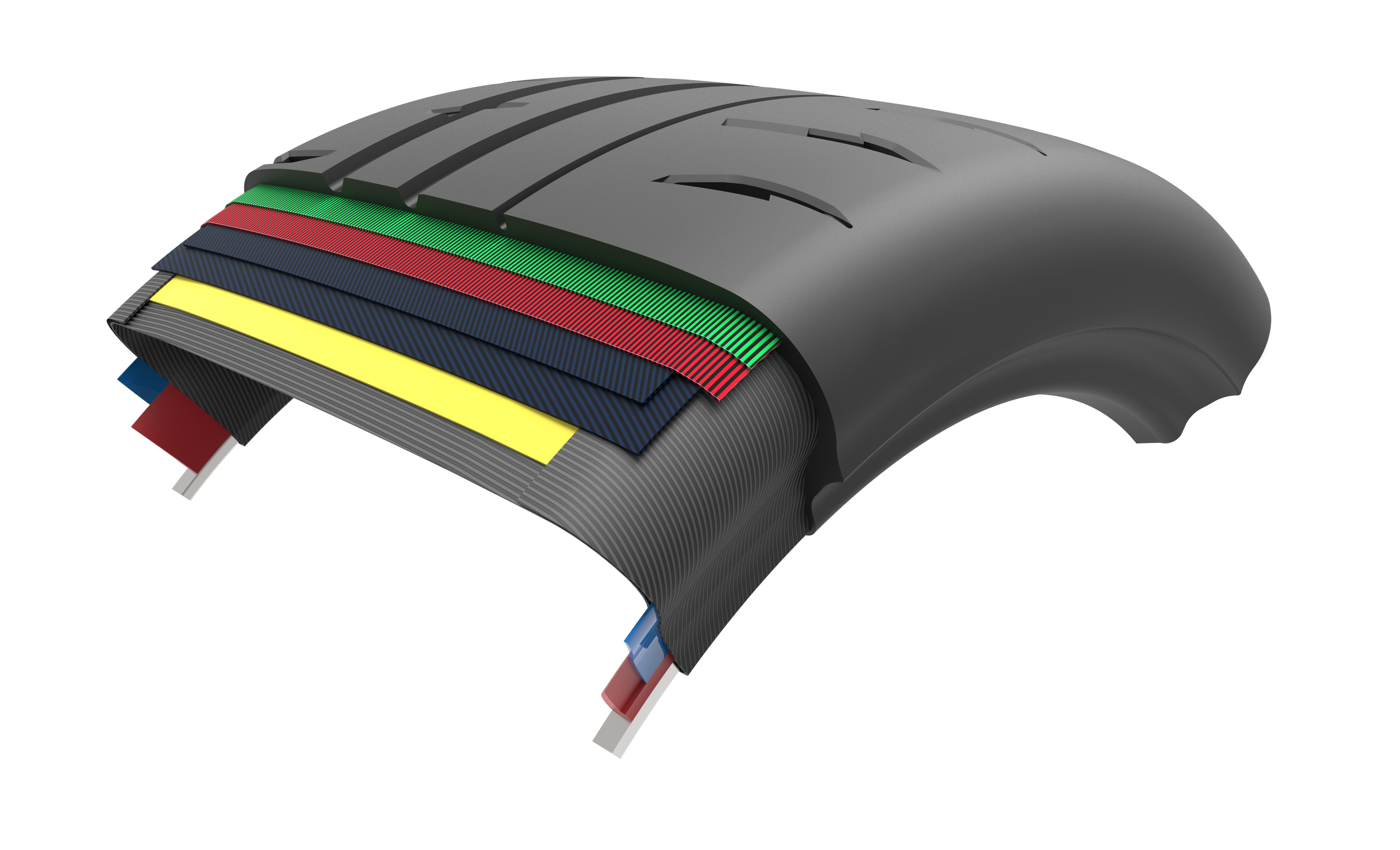

Maxxis’ VR2: A New Option for PB Hunters

Big news for the PB HUNTERS: Maxxis' new VR2 offers the consistency its predecessor was known for and adds a new level of peak grip that earns it a place among the best track day-summer tires on sale today.

Chris’ Evora: Penny-Pinching Pays Off

After a frustrated spell with a supercharged E92 M3 that could never quite put the power down, Chris Mayfield picked up a mid-engined sports car with a higher performance ceiling.

He found the Evora fun and competent in stock trim, and with full aero from Zebulon, it became a record setter.

Cody’s C6 Z06: Father-Son Duo Builds Best Of Both Worlds

Some claim a true street-track car can't be good at anything, but Cody Bulkley thinks otherwise. His background in FSAE and his current role with GM have given him special setup insight to help strike that elusive balance between race car and street car, which is reflected in the performance and versatility of this C6 Z06.

CSG Brake Pads: Details Make the Difference

Thanks to a detailed feedback loop between CounterSpace Garage and their wide array of active customers, they've been able to provide a usable, confidence-inspiring brake pad for every popular HPDE platform today.

Cory’s C6 Grand Sport: Safe Not Sorry

After Cory Smetzler saw the light during a ridealong in a C6 Z06, he bought a Grand Sport from the same generation. It might not have the biggest motor or the lightest chassis in the lineup, but it has a few features which have offered him peace of mind with small few setbacks.

Alex’s FL5 Type R: Best of Both Worlds

The FK8 was too gaudy, the MX-5 was too cramped, and the FL5 was just right. When Alex was able to bring home a new Civic Type R for the occasional track outing, he knew he’d found the best possible compromise within his budget.

Richard’s MR2 Turbo: Not Too Pretty To Pirouette

Although Richard already had an E92 M3, he decided to spruce up his mid-ship sports car and spin his way into driving competence.

Max’s Spec Racer Ford: Lose The Ego

After cutting his teeth in a Porsche, Max got an inkling that going to a lighter, cheaper, more expendable device might expedite his improvement as a driver and budding racer.

Sonoma’s Recent Repave Helps Set New Records

Sonoma’s recent repave — the first in over two decades — has helped Speed SF’s fastest set new records in three of the Challenge groups.

Aidan’s GT3: Vision Realized

Driven to realize a very specific dream built on years of tuning high-revving Hondas, Aidan decided that this 991.2 GT3 would have the subtle cosmetic touches to wow crowds and the high-end racing modifications to set seriously impressive lap times.

Walter’s Sentra: Lifetime Obsession

Twenty years after crewing for various teams in the Spec SE-R series, Walter began racing himself and made a very special Sentra his own.

Hubert's MKIV Supra: Soft Spot

After failing to find an E30 M3 to begin tracking, Hubert decided he’d get his HPDE start in a fourth-generation Supra Turbo: the slinky grand tourer he fell in love with during his teenage street racing days.